Test paper bottle refers to the packaging container used to hold the test paper. The moisture-proof packaging material with certain ability to isolate water vapor will seal the product, isolate the influence of external humidity on the product, and at the same time make the relative humidity in the package meet the requirements of the product. The desiccant moisture content standard in the test paper bottle is referred to the desiccant moisture content standard in the YBB standard for oral solid medicinal low density polyethylene moisture-proof combination bottle cap. The standards are as follows: The desiccant is mainly made of silica gel, large molecular sieve or silica gel: the mixture of large molecular sieve (ratio of 4:6) is mainly composed, and the moisture content shall not exceed 4.8%.

48 mm paper barrel

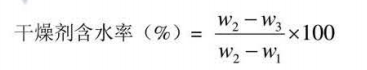

Silica gel desiccant in the relative humidity is not more than 75% of the environment, quickly remove the cap from the sealed bags, and take out 5 ~ 7 g, in has constant weight of the weighing bottle (W1), cheng (W2), plus or minus 10 degrees of 180 degree oven in (from the open bottle caps packaging to the desiccant in the total time put in oven shall not exceed 5 minutes) to a constant weight (weighing for W3), according to the formula, the moisture content shall not be over 4.8%.

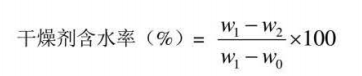

Large molecular sieve desiccants in the relative humidity is not more than 75% of the environment, quickly take out from the closed packing bottle cap right amount, using tweezers to take out the cap of the desiccant, put in has constant weight crucible W0 (8-10 g each crucible), precision said W1, put in 950 degrees high temperature furnace (from the open bottle caps bags to the desiccant in the total time should not exceed 5 minutes) put in high temperature furnace, drying out for 1 hour, crucible cooled precision said W2, according to the formula, the moisture content shall not be over 4.8%.